Widenhorn has developed a unique pick-up module that improves the logistics surrounding laser cutting machines. According to director Anco Euser, logistics is the real challenge. “With higher power consumption and automated sheet metal warehouses, laser cutting machines can produce increasingly more in less time. But then the cut parts are still not ready for delivery or the next process. And how can we always see the location and status of a product without walking into the factory?”

The Pick-up module solves this challenge. It is integrated with PROfirst CAD/CAM, Calculation & Shopfloor software, and with any ERP system. “Our solutions already provided ERP with real-time information about which products in an order were nested or cut,” explains Euser. “Now, it also shows how many were picked.”

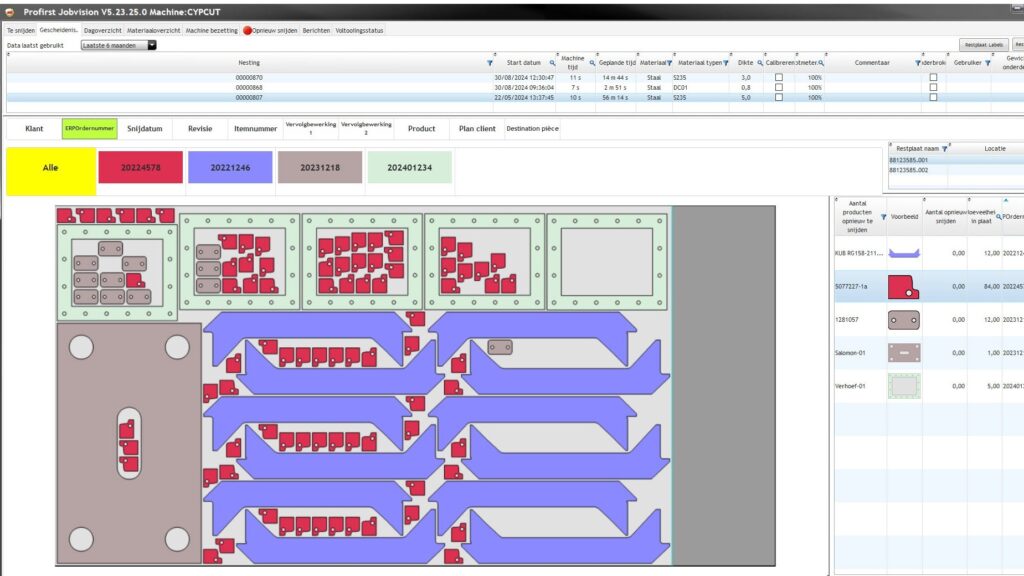

Employees who pick out the nested parts see them on a large screen. They immediately see which order they belong to and can select an available location in the shipping area where they put the products away. These locations are displayed graphically. The location is communicated to the ERP system in real time. This way, everyone in the company knows the location and status of an order. “This way, all logistical information regarding each cutting machine is transparent, without a single piece of paper being touched,” says Euser. “If there’s a rejection, it can be registered immediately. Furthermore, the picking employee can immediately print and label the products.”

The AraapTool provides organizational clarity. The status of an order is known throughout a production facility, even if it consists of many different parts made from different materials. There’s no more searching for products, locations, or paperwork. And because everything is paperless, significant paper savings are achieved. By integrating with ERP, preventing errors, unnecessary searching for products, and product loss, tens of thousands of euros can be saved annually.