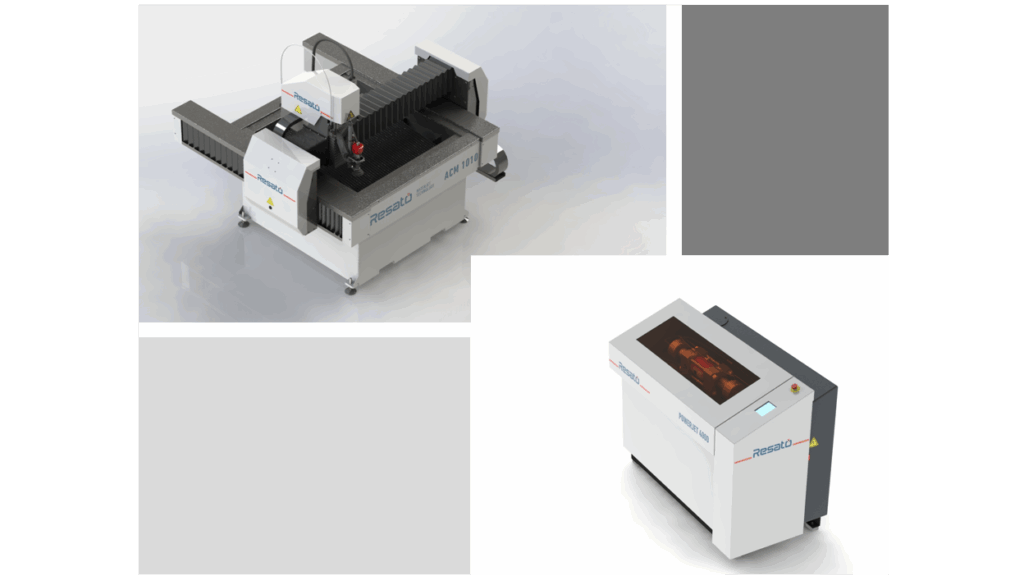

ACM Flex-Zone = Greater efficiency in a safe environment

Previously, the table was inaccessible during cutting, but with the Flex-Zone, loading and unloading can now be carried out safely during the cutting process. This minimises downtime while optimising production and operator working time.

Light curtains are normally installed around waterjet cutting tables to ensure operator safety. With the Resato ACM Flex-Zone, the safety feature is mounted on the bridge itself. It moves with the working area of the cutting head. The Flex-Zone creates flexible, accessible working areas on the cutting table during cutting, allowing operators to access the table.

The ACM Flex-Zone: Greater efficiency in a safe environment!

More efficient cutting process

Unmanned operation

Cleaner working environment

Operation

The ACM Flex-Zone projects a light curtain at the front and rear of the bridge at a standard distance from the cutting head and bridge. Breaking this light curtain while the machine is in operation results in an immediate stop of the cutting head and servo motors, ensuring safe access to the parts on the bridge.

The protected zone can be released in a few clicks via the panel so that cutting can be resumed. While the cutting process is in progress, the operator can load and unload outside the safety zone.