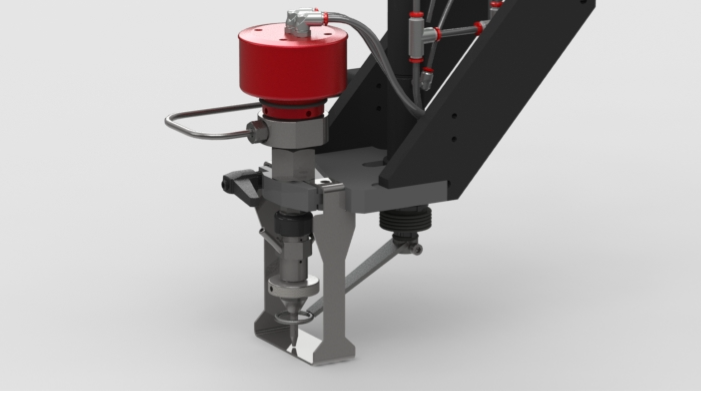

The RS abrasive removal system, equipped with a single filter, consists of a special suction and pressure pipe system, which is fitted with a number of inlet and outlet nozzles mounted in the water tank of the cutting table.

The size of the water tank determines the number of inlet and outlet nozzles. For larger water tanks, the inlet and outlet nozzles are automatically controlled per section by means of a pneumatic valve system.

The water/abrasive mixture pumped out of the water tank is collected in a free-standing separation unit equipped with a filter (known as a Big Bag). The used abrasive sand is sucked out of the water tank and pumped to the RS system. In the RS3 system, the sand settles in a big bag and the remaining water is pumped back to the water tank.

The RS3 system is switched on and off and adjusted from the control console. The Big-Bag filter can be easily removed from the separation unit.

Optional on all ACM series machines

Reduces downtime to a minimum

Reduces the need for tank cleaning

Optimal distance

The maximum distance between the connection points of the cutting table and the RS3 separation unit is approx. 6 metres. This distance is necessary to ensure optimal operation.