Round Brushes: The Key to Efficiency in Deburring Machines

In the world of metalworking, efficiency is everything. Anyone who invests in a deburring machine does so with a clear goal: to apply the right rounding and finish faster and more consistently. But to actually earn back that investment, one factor is crucial: the throughput speed of the conveyor belt. And that is exactly where the quality of the flutter brush comes in.

A high throughput speed is only profitable if the rounding and surface quality are not compromised. The brush must therefore not only be wear-resistant, but also aggressive enough to deburr effectively, without damaging the material. The choice of the right brush material and design plays a decisive role in this.

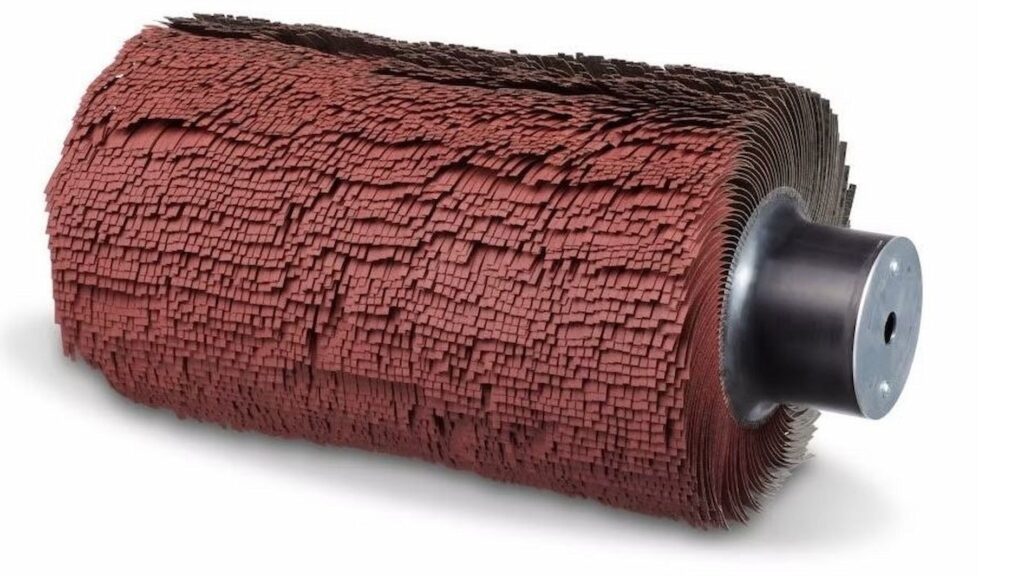

The Cubitron 2™ brushes are specially developed for maximum performance in industrial deburring machines. They distinguish themselves by:

• Cubitron 2™ abrasive grains: patented, triangular ceramic grains that keep themselves sharp and wear evenly.

• Very fast material removal, so more rounding in the same time or the same rounding in half the time compared to traditional abrasive grains

• Constant cutting action: less heat development, less risk of discolouration or deformation of the workpiece.

• Longer lifespan: less downtime, fewer changes, lower costs per part.

The brushes are equipped with a solid core made of lightweight plastic, which ensures:

• Stability at high speeds

• Less vibration, so a more even result and less stress on the machine

• Resistant to the high abrasive forces of the Cubotron 2 mineral

• Faster change time during maintenance

Exclusively at Metaaltechniek in the Netherlands.