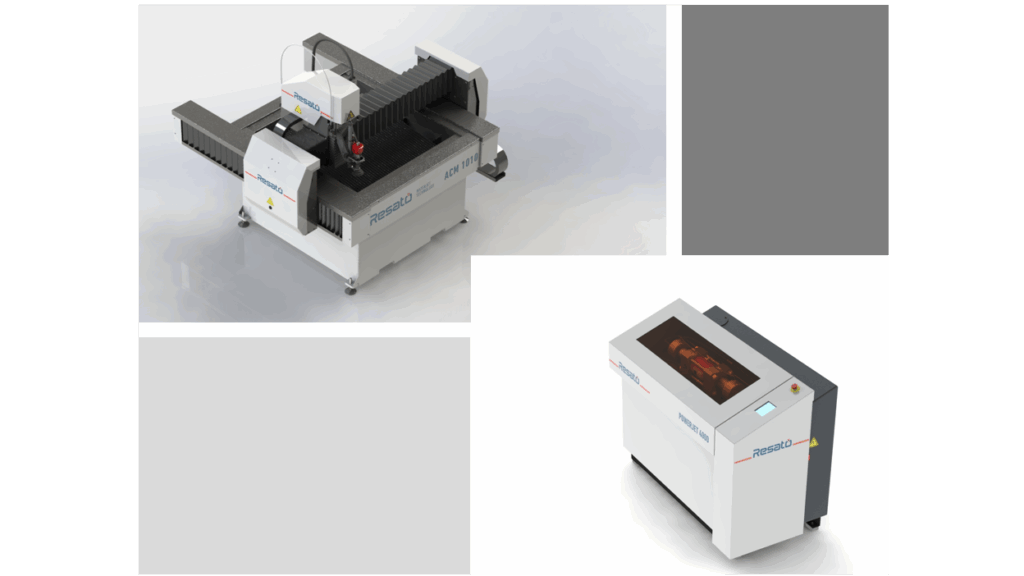

Resato Waterjet is using the Metavak to present innovations. The newly developed ACM1010 is particularly interesting. This compact cutting table offers all the features of larger ACM machines, but with a smaller, yet full, cutting range of 100cm x 100cm. The ACM1010 is designed in a 2D configuration and comes in two different versions: the most striking is the ACM1010-Monoblock. This machine can be moved with a forklift, and the catcher is integrated into the frame. Ideal for smaller workshops, R&D departments, or schools. The standard ACM1010 is constructed like the larger cutting table versions, which vary in width from 2 to 3m and offer an unlimited cutting length range.

The ACM1010 can be combined with the standard PJ4-4000. The 37 kW pump ensures maximum cutting efficiency and maximum pressure. In the Netherlands, the electricity grid infrastructure is increasingly limited, and the available connection values can be challenging. The PJ2-4000 was developed for this purpose. This 18kW pump has similar characteristics to the PJ4-4000. With a nominal current draw of 40A at 400V, it often fits existing connections without expensive network reinforcement. The optimal pressure for this machine is 3500 bar with a 0.25 orifice. More than enough to cut with the desired quality and speed, but with lower energy costs. The PJ2-4000 can also be a good addition to existing pumps, without placing too much strain on the available electricity.

There are more developments, new products, and improvements. One example is the machine HMI display, which has been updated and has a new look and feel. A spray bar keeps the workpiece clean and removes abrasive and process water during unmanned operation. Or the new abrasive feeder, which is even easier to disassemble for maintenance or to clear blockages. And of course, our new, fresh corporate identity will be presented.