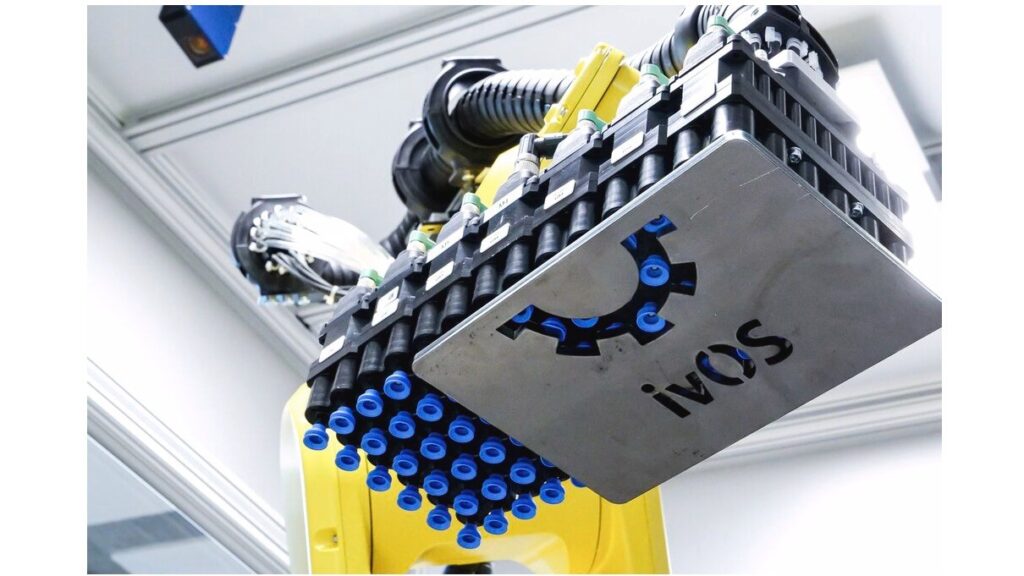

With the Solution Kit, companies can automate machine loading; simple, flexible, and economical. The kit consists of 3D camera technology, the ivOS vision control system, and the highly flexible FMG matrix gripper. This gripper consists of up to 7 modules, each with 12 suction points, forming a flexible, flat gripper. The individually controllable suction points automatically adapt to different workpiece shapes. This offers maximum flexibility in handling various sheet materials and minimizes gripper changes.

Because the gripper system’s control is complex, a learning AI takes over. A camera system is used to recognize unfamiliar workpieces, and the gripper is controlled to optimally pick up the sheet metal.

The control system monitors gripping quality and navigates the robot with the product to the target tray without collisions. All of this happens autonomously, without the user needing specialized knowledge to operate the system. And the best part is that the ivOS software platform works with grippers, cameras, software, and robots from different manufacturers, which can be easily connected and controlled in real time. This also makes it easier to automate other applications in the future.